St. Louis Rocketry Association had a launch yesterday in Elsberry, MO and I took GJaH for its shakedown flight.

The main problem appears to be stability. In OpenRocket, based on the actual weight and balance of the finished rocket, it had 1.15 calibers of stability margin off the pad. The rule of thumb is that one caliber is required for stability, but in this case, the rocket is 2.25 inches diameter and almost 8 feet long. Clearly, from watching this flight, it needed more.

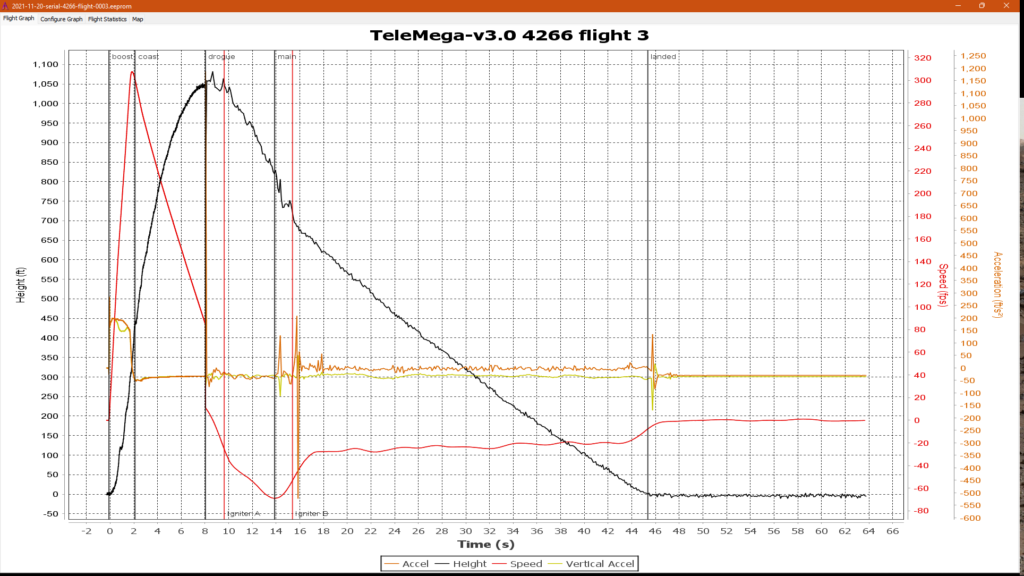

Here’s a timeline I made from the on-board video:

- T-0: Liftoff

- T+2.0s: Booster burnout

- T+8.0s: Apogee (1048 feet AGL)

- T+10.0s: Very high roll rate under streamer; booster appears to partially drag separate

- T+14.0s: Main parachute ejection and booster ejection at roughly the same time

- T+17.5s: Main parachute is inflated

- T+24.2s: Chute Release seen to be open (could have been as early as T+21.7s)

- T+26.0s: Booster parachute is seen to be inflated (could have been slightly earlier)

All of the electronics worked as designed. I had thought through several failure modes, of which this was the most likely, so everything was set up to allow a safe recovery if the stages were still connected together, although the descent rate was a bit higher than it would have been without the additional weight of the sustainer propellant.

Stability. For the next flight, I plan to add nose weight to increase the stability margin. OpenRocket indicates that 8 ounces of additional weight in the nose would have increased the stability margin to around 2.5 at the cost of about 250 feet of altitude. Counter-intuitively, the extra nose weight actually increases the expected altitude of my planned J-420 to J-150 flight by about 400 feet. A higher-thrust booster motor might also help the rocket fly straighter on the first stage. The I-303 and I-470 are higher-thrust alternatives that are available, and simulations of either one indicate an expected apogee around 7300 feet, the same as would have been expected for this flight if the upper stage had fired.

Sustainer delay. I think there’s some conventional wisdom that shorter delays between booster burnout and sustainer ignition are safer, but I think that comes from a time when the electronics were not as sophisticated as they are now. With the setup I’m using, longer delays seem to be safer since the rocket’s tilt angle is measured for the entire delay period, making it more likely that the EasyTimer will “see” an unsafe attitude and abort the ignition.

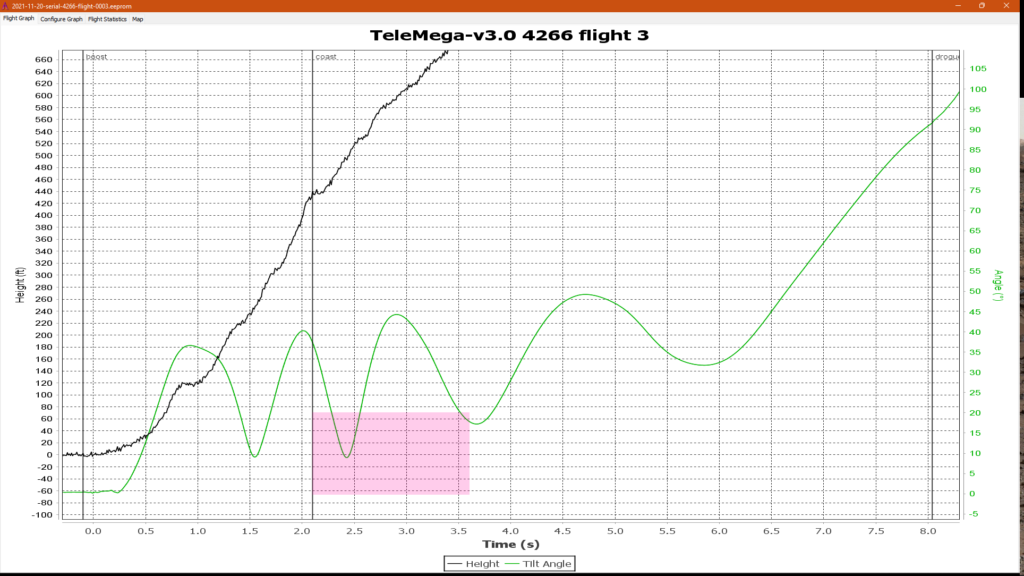

This is a zoomed-in graph showing GJaH’s tilt angle vs. time. The shaded box shows the “safe” area of 0-20 degrees of tilt and the 1.5 second sampling period after booster burnout. My understanding of the EasyTimer’s programming is that the tilt angle must not go above 20 degrees at any point during that 1.5 seconds to allow sustainer ignition.

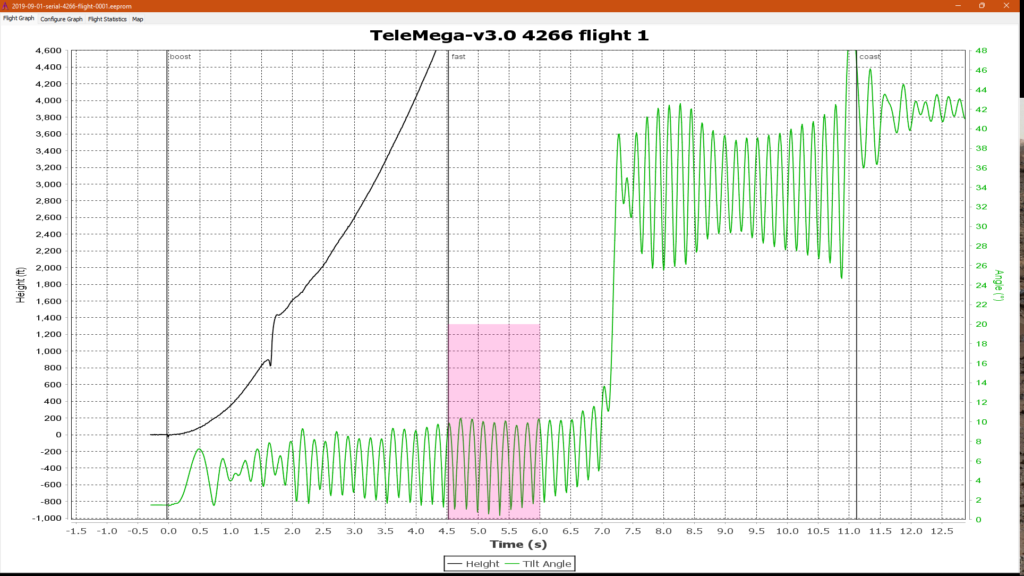

For comparison, here’s the same graph using Kestrel’s flight data from 2019. If this had been a two-stage flight, sustainer ignition would have been allowed since the line stays within the shaded area. For the next flight, I plan to optimize the delay period for maximum altitude and not worry about it being too long.

Other possible changes between now and flight #2…

- Assembly at the pad was very difficult since I did not have enough slack in the igniter wire. I left eight inches past the nozzle but more of that wire ended up inside the interstage than I thought due to the way the wires have to be folded in order to fit. This resulted in not having enough clearance to tape the igniter to the nozzle as I had planned on my checklist. I’ll change my prep procedure to leave another six inches or so.

- The fly-away rail guide for the sustainer didn’t work because it puts the rail buttons further from the tube than the buttons on the booster section. I’m not sure I’ll have a solution for this, but I’ll think about it. I do have another guide I can try. The purpose of the sustainer guide was to guard against a failure mode in which the sustainer lights on the launch pad and would be uncontrolled.

- Both 3D-printed antenna protectors broke, either in flight or upon landing. I’ll try to think of a better solution there.

- I second-guessed myself and friction-fit two of the separation points (sustainer coupler to lower airframe and interstage to booster) instead of shear pinning them. Mostly this was due to the fact that I had no way of ground testing them. In the flight video, you can see the booster section beginning to come loose during flight (note than after a certain point in the video, the booster fins are no longer aligned with the sustainer fins). However, the flight was much more chaotic than it should have been, so all of the extra pitch and yaw might have contributed to that. These friction points will either need to be made tighter, or I will have to go back to shear pins.

- For some reason not yet clear to me, the rocket rolled really fast while it was in the configuration where the apogee streamer was out but nothing else had separated yet. The streamer I used was a relatively small 2″x40″ streamer, and I only used it because the only larger one I had was the 6″x100″ that I use for Black Widow and other larger rockets. For the next flight I may try a small drogue parachute instead of a streamer to try to keep things under control.

- I came to find out that the “small” plastic pop rivets I’ve been using are actually of two very very similar yet not quite the same sizes. GJaH’s airframe is drilled for the very very slightly smaller size, so most of the rivets I took to the field with me, which were of the very very slightly larger size, did not fit. As a result, I flew it with only two rivets instead of three, which works fine but is annoying. Actually, using those rivets has been a constant annoyance, and I’ve used them on every HP project I’ve ever built. I need to put some thinking time into trying to come up with a better solution. (Small bolts and t-nuts, maybe? Backing t-nuts inside the tube would be tricky since the sled still has to slide in and out.)

- Drill the wiring holes in the sustainer bulkhead out another 1/64″ to make threading the wire bundles easier.

- Probably replace the TeleMega wiring at the same time.

GJaH on the pad

Liftoff

20 degrees off vertical, T+0.6s

Corkscrew exhaust trail

Corkscrew exhaust trail

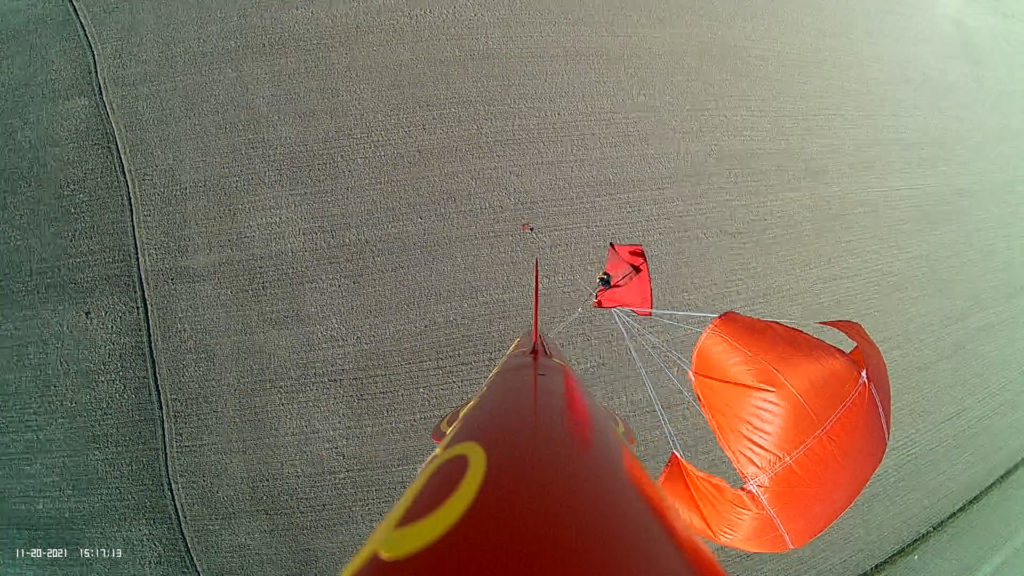

Apogee ejection

Booster ejection

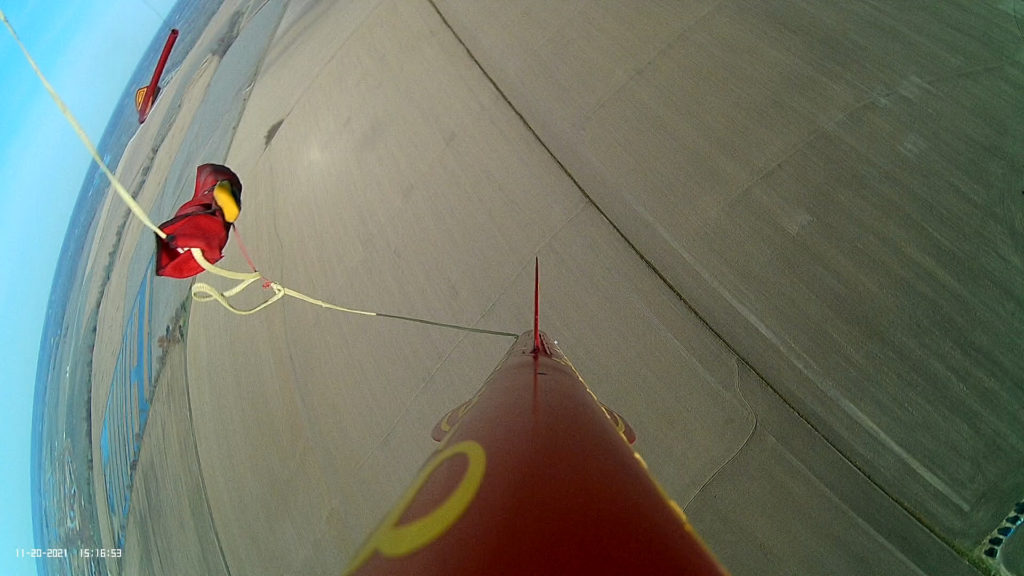

Booster parachute with Chute Release

Booster parachute inflated

Booster and lower airframe landed, sustainer upper airframe seen in the air

Landed with all recovery devices deployed

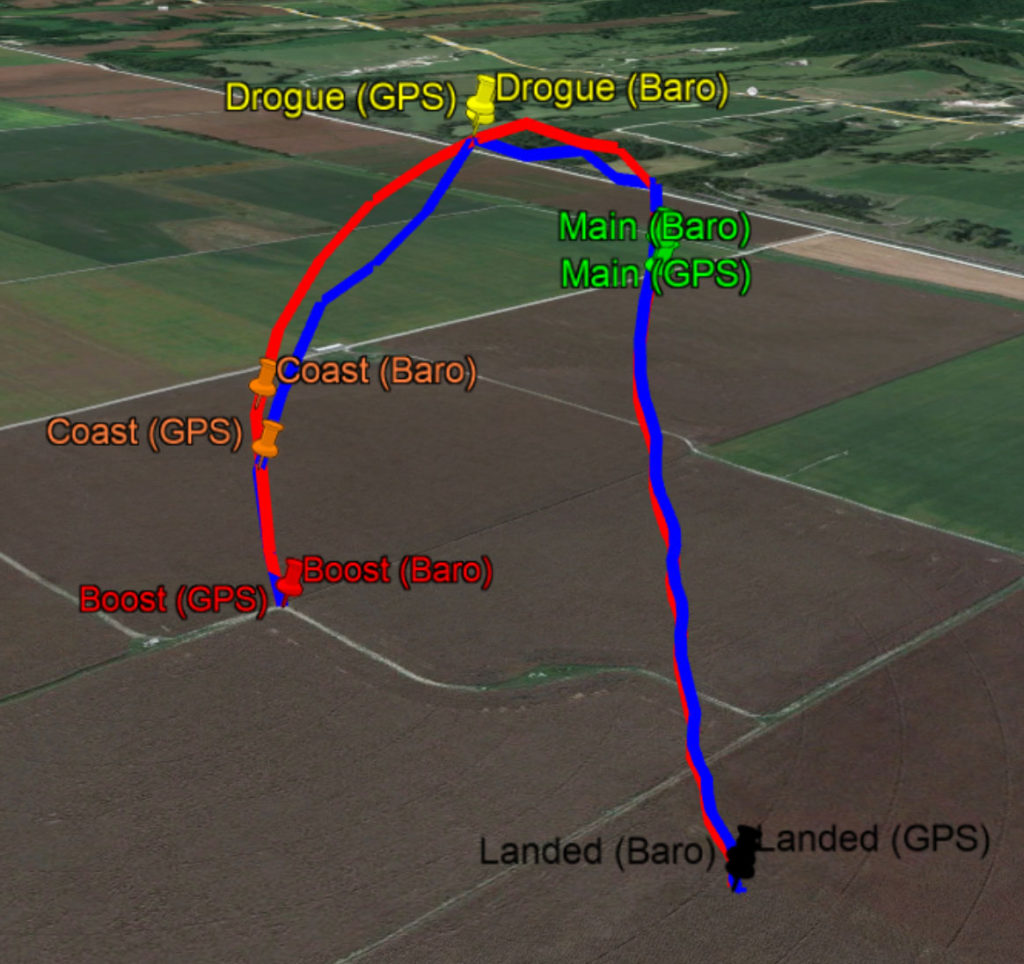

GPS track of flight